The construction estimating and tendering function within construction organizations plays a crucial role in ensuring that projects are financially viable and competitively priced. We will delve into the various components, personnel, workflows, and best practices that shape the estimating and tendering process. This article expands on those insights to present a holistic understanding of how construction estimators operate and why their role is central to a company’s success.

In the fast-paced and cost-sensitive world of construction, the accuracy of an estimate can determine whether a contractor wins or loses a bid. Beyond this, a well-prepared estimate ensures that the awarded contract remains profitable and free from costly surprises. The estimating process involves not just mathematical calculations but also judgment, experience, and foresight. Estimators must interpret architectural drawings, analyze labor requirements, evaluate subcontractor quotations, and apply financial strategies—all while considering external factors such as inflation, supply chain disruptions, or changes in building regulations.

This comprehensive approach to estimating supports a company’s reputation and trust with clients. It also builds internal confidence that projects will be delivered on time and within budget. Ultimately, the success of a construction business hinges on the reliability of its cost planning, making the role of the estimator not only technical but also strategic.

2. Organizational Structures and Team Composition

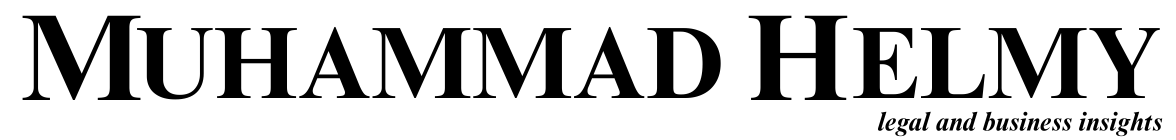

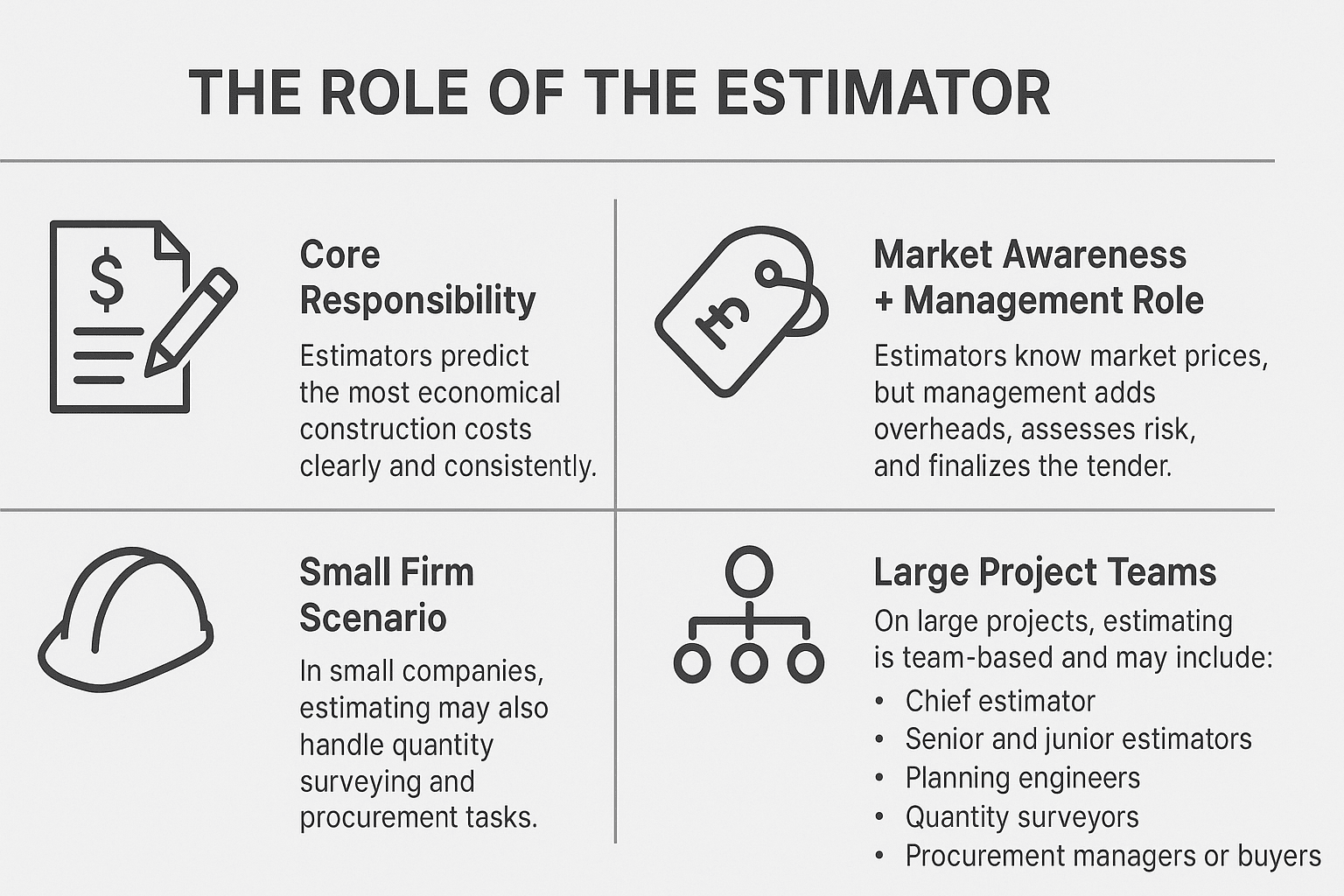

The structure of the estimating function within a construction firm varies depending on the company’s size, project portfolio, and operational complexity. In small firms, estimators often play hybrid roles, acting not only as cost planners but also as buyers, quantity surveyors, or even site coordinators. This versatility is necessary due to limited staffing and budget constraints, and it fosters a deep understanding of the entire project lifecycle.

In contrast, large construction firms often deploy specialized teams where each member is dedicated to a specific function. A typical setup might include a chief estimator leading the department, supported by senior estimators responsible for overseeing major packages of work, and junior estimators or trainees handling data entry, preliminary calculations, and document preparation. Estimating assistants may be assigned to verify data accuracy, maintain records, and facilitate communication between departments.

This hierarchical model not only promotes efficiency but also serves as a pipeline for developing future talent. Many firms rotate junior estimators across various roles, allowing them to gain exposure to different construction disciplines. Mid-sized firms usually strike a balance, with teams that are lean yet sufficiently diverse to manage complex bids. These teams are often integrated with other departments like planning, procurement, and finance, allowing for real-time exchange of critical project data and collaborative decision-making.

The success of a tendering department hinges on the synergy between these diverse professionals. Effective teamwork ensures that estimates are not prepared in isolation but reflect a comprehensive understanding of technical constraints, market conditions, resource availability, and client expectations.

3. Detailed Responsibilities and Interdepartmental Collaboration

Estimators are central figures in any construction project’s early stages. Their responsibilities extend far beyond preparing cost sheets. As coordinators of all cost-related matters, estimators must interact regularly with a wide range of professionals to assemble a realistic and comprehensive tender. This collaboration is key to identifying constraints, optimizing methods, and ensuring that no critical aspect is overlooked.

For example, the planning engineer provides time-related insights by developing preliminary schedules and method statements. These documents help define how the work will be carried out and ensure that assumptions about project durations are reasonable. Accurate planning is vital in fast-track projects where delays can be financially punitive.

Quantity surveyors add another layer of commercial evaluation. They assess potential risks in the contract, scrutinize amendments to standard terms, and estimate financial exposure in case of delays, material shortages, or disputes. Their insights are particularly useful for projects involving complex contractual arrangements such as public-private partnerships (PPPs) or design-and-build frameworks.

The buyer or procurement manager plays a pivotal role in ensuring cost efficiency. By sourcing competitive quotations and maintaining relationships with trusted suppliers and subcontractors, they help build a reliable and cost-effective supply chain. Estimators often consult buyers to understand recent market fluctuations, seasonal price shifts, and availability of key materials or equipment.

Moreover, input from site managers—especially from recently completed projects—helps estimators learn from real-world outcomes. For instance, if a particular method proved inefficient on a previous site, that insight can influence the approach for upcoming bids. This feedback loop is invaluable for continuous improvement and risk mitigation.

Ultimately, interdepartmental collaboration transforms estimating from a numerical exercise into a strategic, knowledge-driven process that boosts a contractor’s chances of success.

4. Estimating Workflow and Tendering Procedures

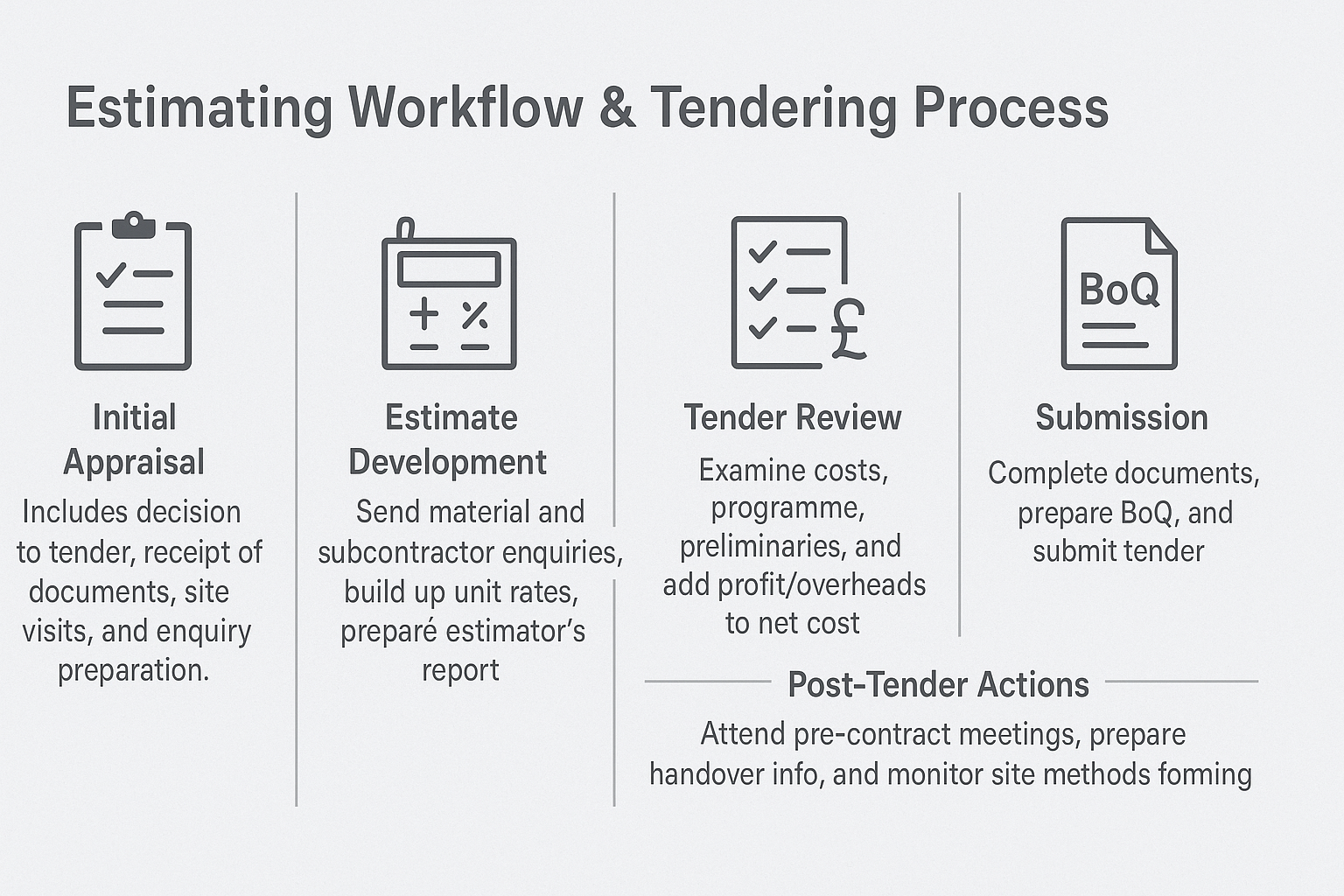

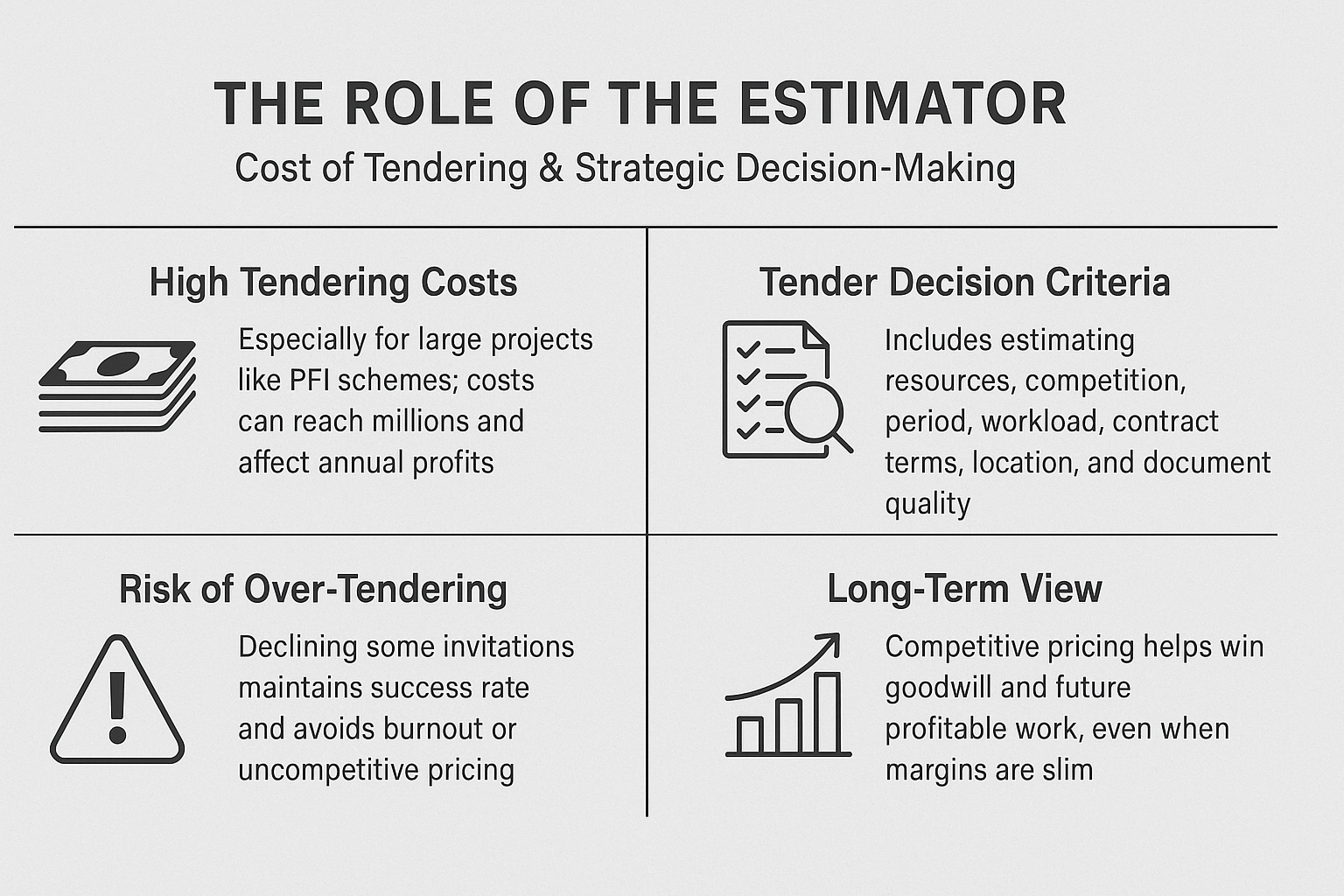

The estimating workflow is a structured, multi-phase process designed to ensure thoroughness, accuracy, and competitiveness in pricing. It begins with an internal appraisal phase where the contractor reviews the invitation to tender and determines whether to proceed. This decision is not taken lightly, as the cost of preparing a tender—especially for large projects—can be substantial.

Once the go-ahead is given, the estimator’s first step is to conduct a detailed examination of the tender documents. This includes analyzing architectural and engineering drawings, specifications, site conditions, and contract terms. During this stage, the estimator identifies potential challenges, such as difficult access points, environmental constraints, or stringent regulatory requirements, and begins to consider appropriate construction methods and resources.

The next phase involves sending out enquiries to suppliers and subcontractors. Estimators must ensure that these parties are reputable and capable of delivering on time and within budget. This procurement phase is followed by the development of resource plans, where labor and plant outputs are estimated, and rates are applied based on historical data, current market rates, and project-specific conditions.

Pricing preliminaries is a particularly nuanced task. These are indirect costs such as site setup, utilities, temporary works, safety provisions, and project management overhead. Errors in preliminary pricing can significantly affect the overall estimate and, ultimately, the profitability of the contract.

All findings are compiled into an estimator’s report, which undergoes internal adjudication. Senior management reviews the proposed estimate alongside risk assessments and resource strategies. Final adjustments are made, including the addition of overheads and profit margins, to arrive at a net tender figure.

Finally, the prepared tender is submitted according to the client’s instructions—often electronically and within a tight deadline. A well-organized workflow ensures that tenders are submitted on time, professionally formatted, and competitively priced.

5. Planning Tools and Resource Monitoring

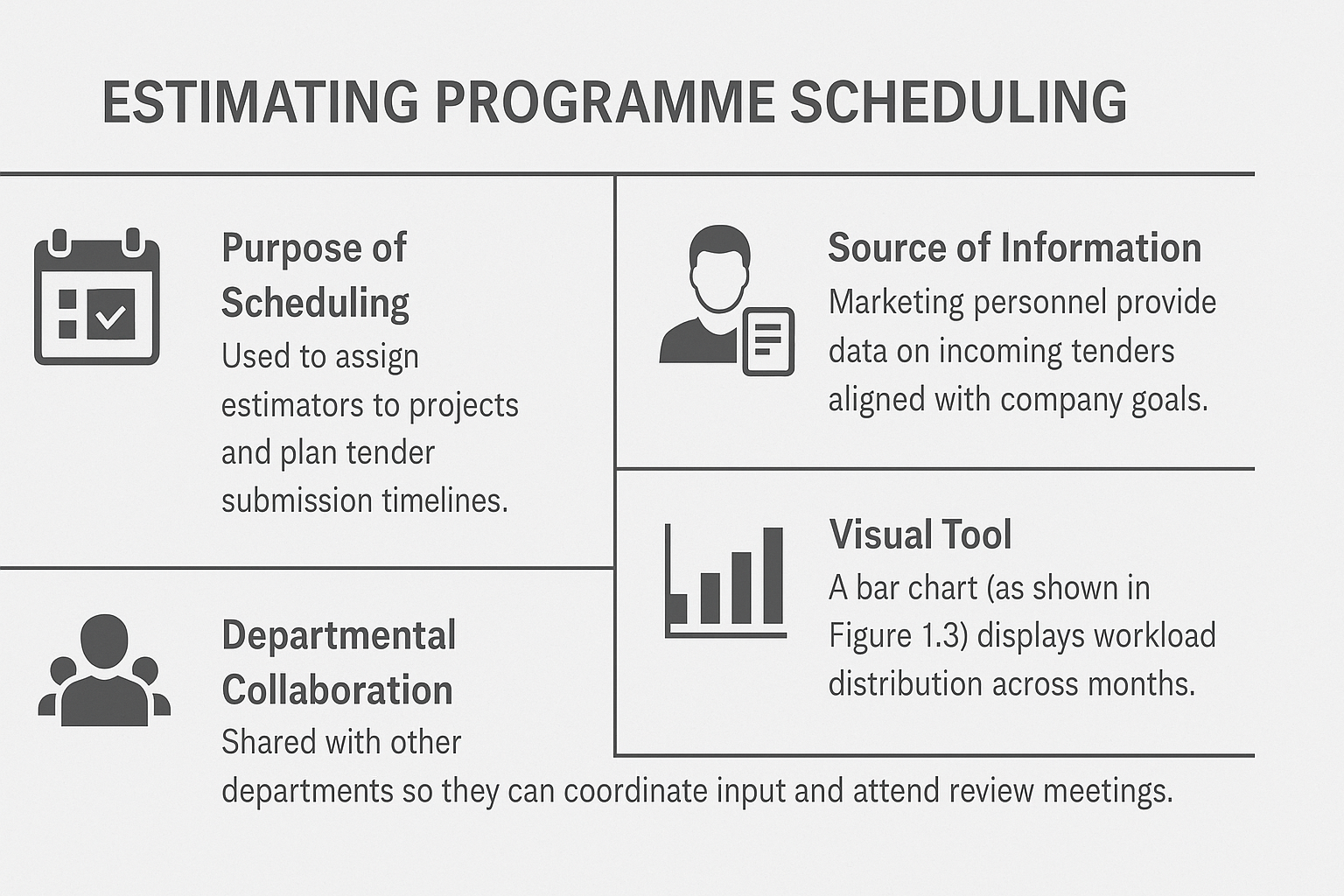

Efficient planning and monitoring are essential to ensure that the estimating department operates at peak productivity and delivers high-quality outputs. Estimators must manage multiple tenders simultaneously, often under tight deadlines. To do this effectively, organizations use a range of planning tools that provide visibility, accountability, and structured coordination.

One commonly used tool is the estimating programme—a bar chart or Gantt chart that visually displays upcoming tenders, their respective deadlines, and the staff allocated to each. These charts are often color-coded and include symbols for review meetings, submission dates, and staff availability (e.g., holidays or part-time assignments). They serve not only as scheduling aids but also as communication instruments between departments.

For example, a chart might show that Estimator A is working on two tenders due within the same week, which may prompt the chief estimator to reassign one to Estimator B. This proactive balancing of workloads helps prevent bottlenecks and ensures that each bid receives adequate attention and due diligence.

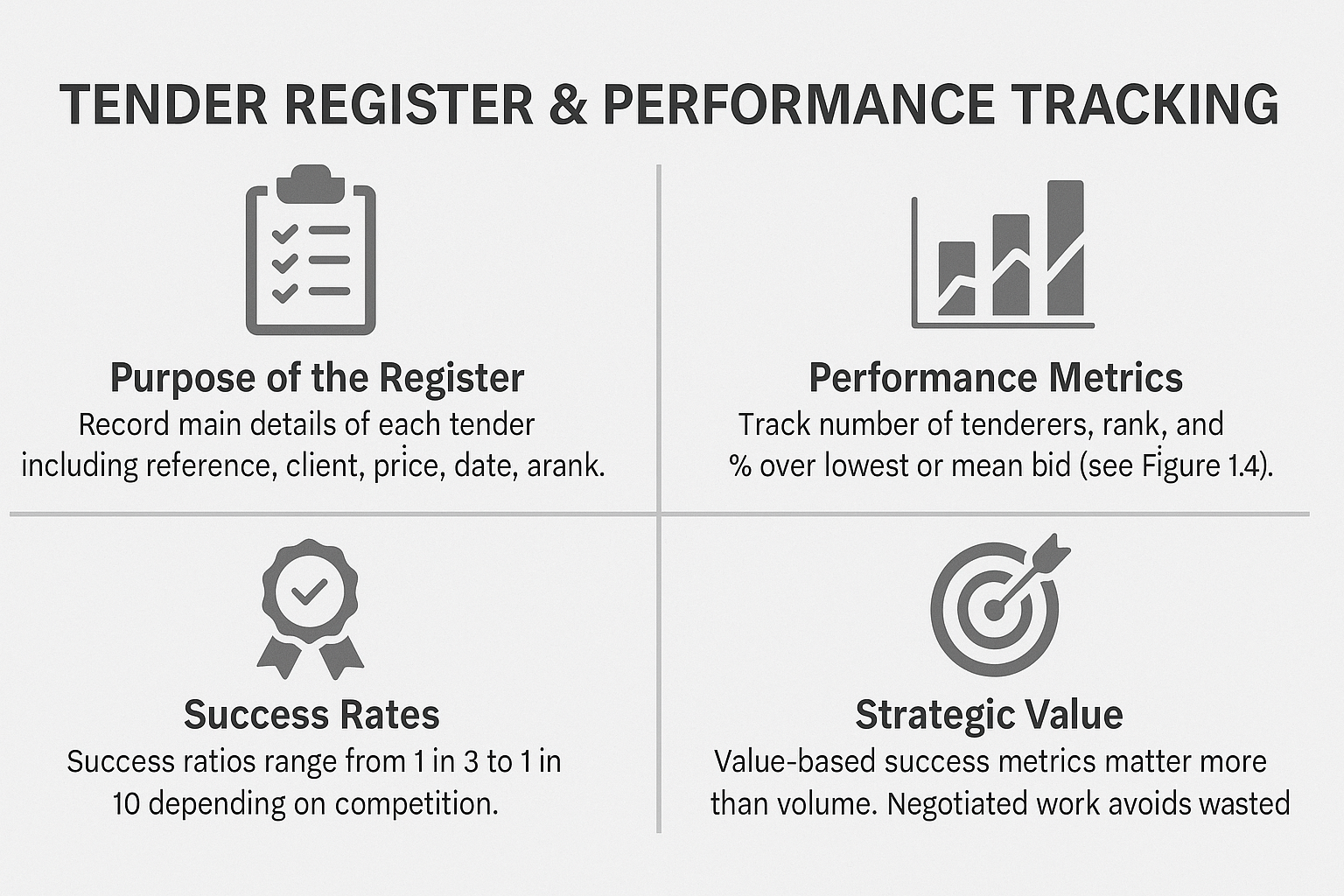

The tender register is another critical planning tool. It records vital information such as the tender number, project title, client name, submission date, tender value, and success status. Over time, this log becomes a valuable performance metric. It reveals patterns like win rates by project type, client responsiveness, or competitive pricing trends. For instance, a firm might discover that it wins more retail-based contracts than infrastructure projects, influencing its future bidding strategy.

Digital solutions are increasingly used to manage these tools. Cloud-based platforms allow team members to update progress in real-time, and dashboard analytics help managers track key performance indicators. Ultimately, planning tools allow estimating departments to function with precision, transparency, and adaptability in a demanding industry.

6. Measuring Success

Success in estimating and tendering is not merely about the number of bids submitted—what matters most is the value and profitability of the contracts won. Estimators must operate in a competitive market where win ratios can vary dramatically, often ranging from one in six to one in ten. However, these statistics can be misleading if not contextualized. For instance, a contractor might lose five low-value bids but win a single high-value project that more than compensates for the cost of the failed attempts.

Therefore, many companies now focus on success metrics based on contract value rather than volume. By analyzing tender registers and historical performance data, companies can assess which types of projects yield the highest returns, which clients are most responsive, and what bidding strategies are most effective. This data-driven approach allows companies to prioritize tenders with the greatest strategic or financial value.

Key performance indicators (KPIs) used to measure success include bid-to-win ratio, average bid value, and cost of bid preparation. Firms may also track time spent per estimate and the variance between estimated and actual project costs. A consistently narrow variance is a sign of an experienced estimating team that understands construction variables well.

Additionally, negotiated contracts—often based on established relationships or framework agreements—are highly valued. They eliminate the risk and expense of open competition and usually provide more stable profit margins. Estimators must still prepare detailed costings for these contracts, but the process allows for more collaboration and customization, which benefits both client and contractor.

In sum, success in estimating is a blend of financial acumen, market understanding, and strategic bidding. Continuous improvement, guided by performance metrics, is essential to maintaining competitiveness in a rapidly evolving construction landscape.

7. Career Pathways and Skill Requirements

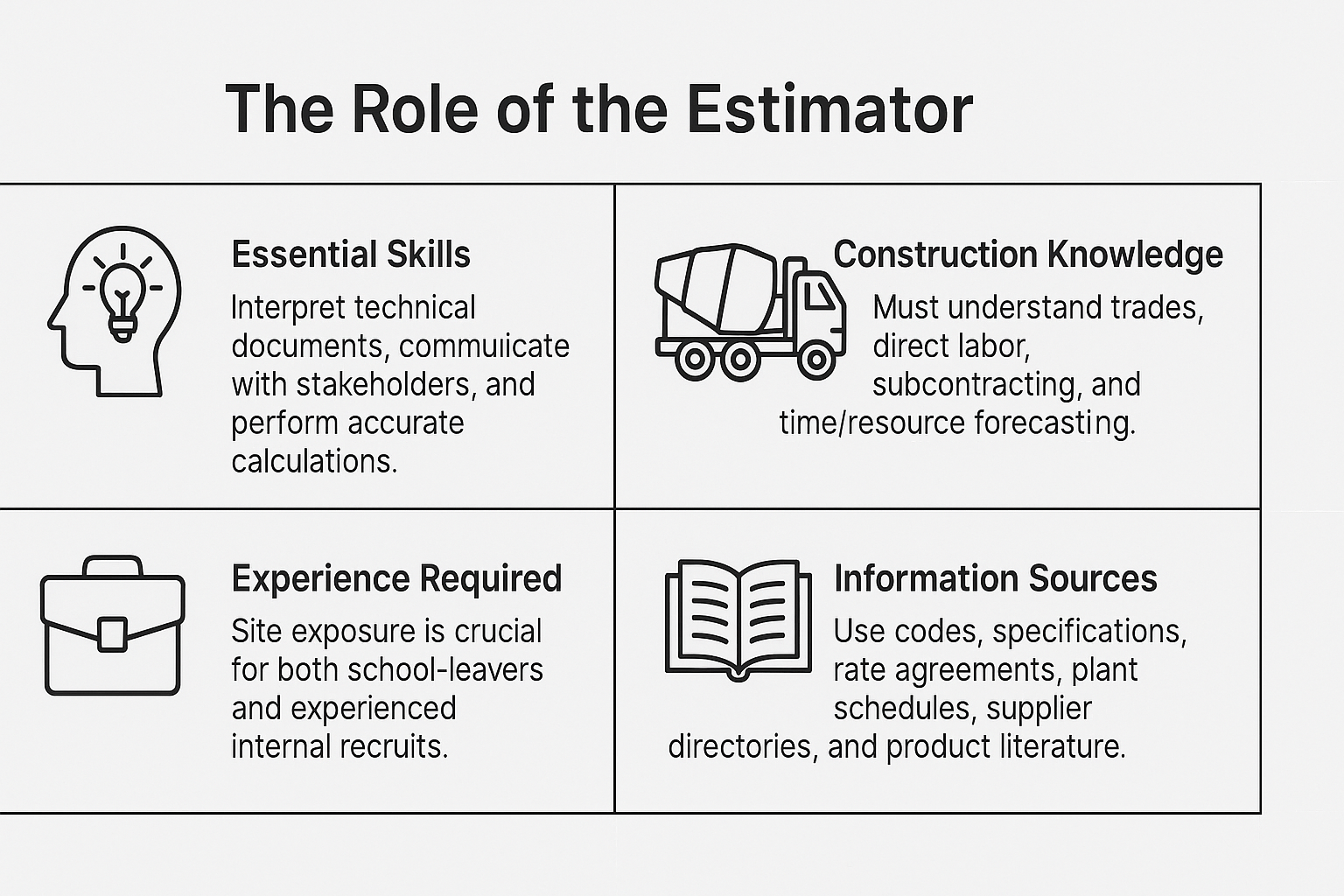

Becoming an estimator in the construction industry is both a technical and strategic journey. Individuals typically enter the field through two primary pathways: academic education or internal promotion. School leavers with strong performance in subjects like mathematics, physics, or technical drawing are ideal candidates for further vocational training in quantity surveying or construction management. These individuals may join companies as trainee estimators or junior assistants and gradually acquire the…

Alternatively, many estimators begin their careers on-site in roles such as site engineers, supervisors, or quantity surveyors. Over time, they transition into office-based estimating positions based on their practical knowledge and analytical skills. These internal promotions are especially valuable because such estimators bring real-world construction experience, allowing them to assess cost implications with a deeper understanding of on-site realities.

Regardless of the entry path, estimators must master a unique blend of skills. Technical proficiency is essential—they must interpret architectural and engineering drawings, understand specifications, and work with detailed pricing documents. They should also be adept at using software tools for cost modeling, data analysis, and digital tender submissions.

Equally important are soft skills. Estimators need strong communication abilities to coordinate with architects, consultants, suppliers, and internal teams. They must also demonstrate good judgment, attention to detail, and the ability to work under pressure. Inaccuracies or oversights in estimates can lead to underbidding—resulting in financial losses—or overbidding, which could cause the firm to lose out on valuable contracts.

Professional development is ongoing. Many estimators pursue chartered status or certifications from bodies like the Royal Institution of Chartered Surveyors (RICS) or the Chartered Institute of Building (CIOB). These qualifications not only enhance credibility but also keep estimators updated with evolving industry standards, legal frameworks, and digital tools.

8. Information Resources and Technical References

A competent estimator must navigate a wide array of technical references and data sources to deliver accurate and reliable cost projections. These resources form the backbone of every estimate, ensuring that pricing reflects not only current market conditions but also aligns with industry standards and contractual obligations.

The Code of Estimating Practice (COEP) is one such critical document. It provides a structured approach to estimating, offering guidance on work breakdown structures, rate-building procedures, and documentation standards. By adhering to COEP, estimators can ensure consistency, compliance, and traceability in their cost assessments.

Another foundational tool is the Standard Method of Measurement (SMM), which defines how quantities of construction work should be described and measured. This standardized language ensures that estimators, contractors, and clients are all “speaking the same language,” thereby minimizing misunderstandings during contract execution.

Labor costs are referenced using the National Working Rule Agreement, which outlines pay rates, overtime entitlements, and working conditions across various trades. Similarly, the Definition of Prime Cost of Daywork and Daywork Plant Schedules guide estimators in pricing works done outside the original contract scope, usually in emergency or unforeseen situations.

Estimators also rely on a wealth of trade literature and supplier directories. These sources provide up-to-date pricing for materials, availability of products, and supplier qualifications. In competitive tendering, even small differences in unit costs can determine the outcome of a bid, making these resources vital.

In recent years, digital transformation has revolutionized how estimators access and use this information. Online databases, cost modeling software, and integrated ERP systems enable real-time updates, collaborative workflows, and data-driven decision-making. Mastery of these tools enhances the estimator’s efficiency and allows firms to respond swiftly to changes in scope, design, or market conditions.

9. Quality Assurance in Estimating

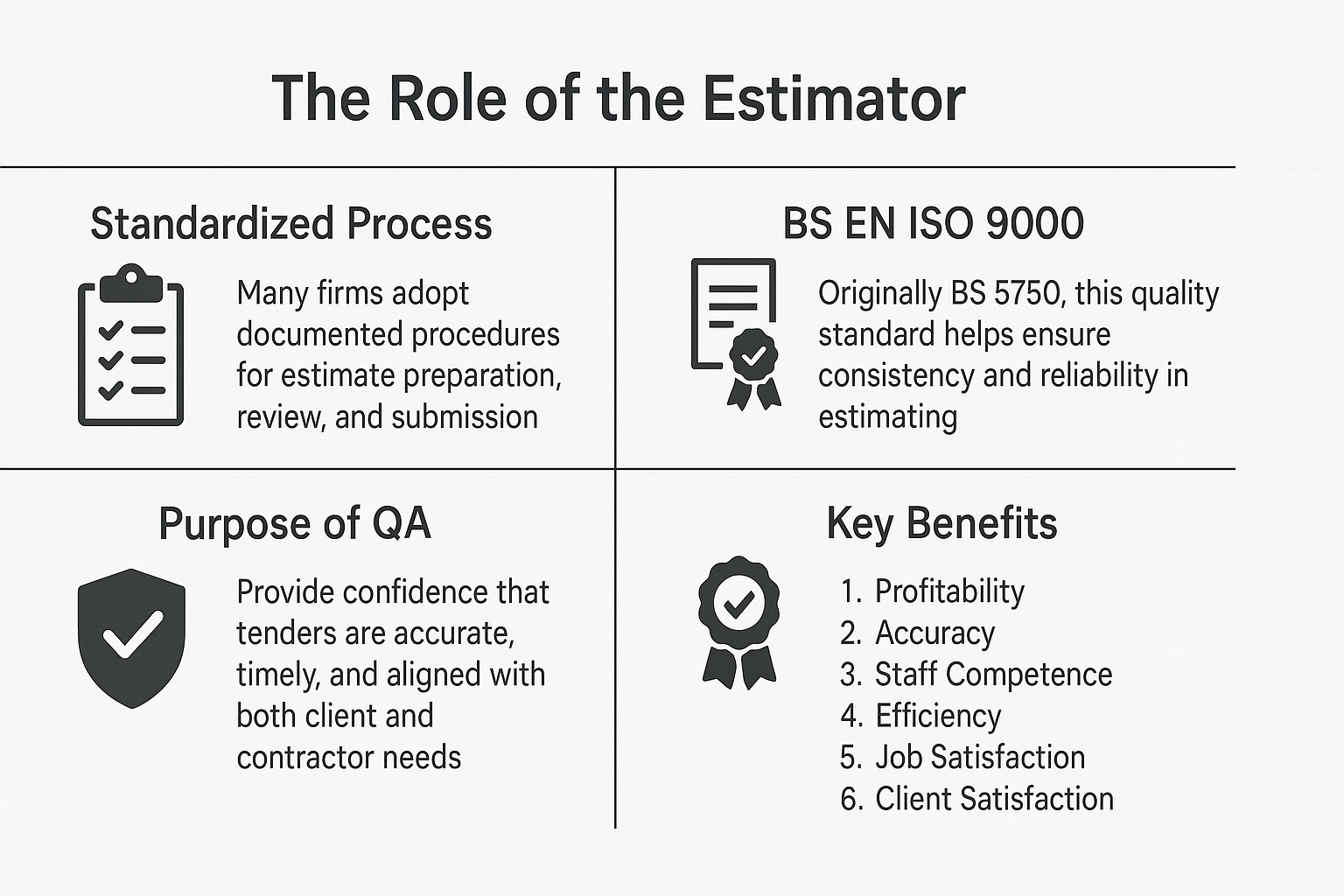

Quality assurance (QA) in the estimating function ensures that the process of preparing tenders is systematic, consistent, and aligned with both internal policies and client expectations. In the highly competitive construction industry, a reliable QA framework can make the difference between winning and losing bids—particularly in large-scale public projects where scrutiny is intense.

At the core of this assurance is compliance with industry standards such as the BS EN ISO 9000 series, which evolved from the earlier BS 5750. These standards set out requirements for a quality management system, focusing on processes that ensure repeatability, accountability, and traceability. For estimating departments, this translates into standardized procedures for document control, peer review, authorization hierarchies, and final tender submission.

Companies that implement QA systems in estimating benefit in several ways. First, there is a noticeable reduction in errors and omissions. This is particularly critical in pricing, where a single miscalculation can lead to underquoting and project losses. Second, QA processes improve organizational learning. For instance, past estimates and feedback from completed projects are reviewed to update rate databases and refine forecasting methods.

In addition, quality systems create a structured onboarding process for new staff. Clearly documented procedures allow junior estimators to understand expectations and follow best practices from day one. This contributes to better training outcomes and a stronger departmental culture of accuracy and professionalism.

Quality assurance also builds client trust. When clients receive professional, well-organized tenders that demonstrate clear assumptions and risk assessments, they are more likely to view the contractor as capable and reliable. Over time, this credibility leads to more invitations to tender and an improved rate of success.

In summary, quality assurance in estimating is not just a technical protocol—it is a strategic asset that enhances profitability, professionalism, and client relationships.

10. Health, Safety, and Legal Compliance

Modern construction estimating must incorporate robust allowances for health, safety, and compliance with legal frameworks. The responsibilities of estimators now extend well beyond cost projections—they must also ensure that their estimates reflect the regulatory environment in which the project will be executed.

One of the key legislative frameworks influencing construction safety is the Construction (Design and Management) Regulations 1994, which places significant responsibility on designers and contractors to plan for safe construction methods from the outset. Estimators working on design-and-build projects must factor in costs for safety signage, personal protective equipment (PPE), safe working platforms, and temporary structures like scaffolding or hoardings.

More critically, a pre-tender Health and Safety file is often prepared by the client’s consultant team. This document outlines known hazards on the site—such as underground utilities, contaminated soil, or structural instability—as well as risks inherent in the design. Estimators must read this file carefully and include line items for any specific control measures or mitigation strategies that will be required.

In projects involving demolition, excavation, or hazardous materials, safety costs can form a substantial part of the preliminaries. These costs are not optional; underestimating them can result in serious legal and financial consequences. If an incident occurs and it is found that the contractor did not price for adequate safety provisions, the company may be held liable for negligence.

Compliance with local labor laws, environmental regulations, and construction codes must also be reflected in the pricing. This includes considerations for noise control, working hours, dust suppression, and waste management. International projects may also require adherence to foreign safety standards, making due diligence and expert consultation essential.

Ultimately, pricing for health and safety is not a burden but a mark of a responsible and forward-thinking contractor.

Conclusion

Estimating and tendering represent the financial blueprint of any construction endeavor. From the smallest residential build to the largest infrastructure project, success begins with a thorough, accurate, and compliant estimate. As this article has demonstrated, the estimating process is deeply collaborative, technically complex, and strategically essential.

The role of the estimator has evolved in recent decades. No longer confined to calculators and spreadsheets, today’s estimators must harness digital tools, analyze legal documents, coordinate across departments, and maintain client relationships—all while meeting tight deadlines. The need for continuous learning, adaptation to market changes, and integration of health and safety measures underscores the estimator’s role as both a technician and a strategist.

Organizations that invest in robust estimating processes—supported by trained personnel, quality management systems, and modern planning tools—position themselves as leaders in the construction market. These firms not only bid smarter but also deliver more predictable project outcomes, maintain higher client satisfaction, and build long-term business resilience.

In the end, good estimating is not just about numbers—it is about building trust, demonstrating competence, and laying the groundwork for construction excellence.